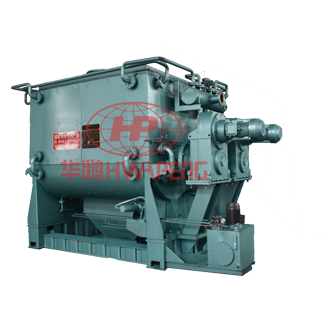

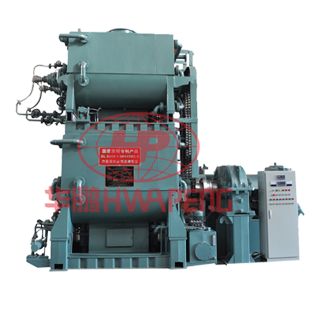

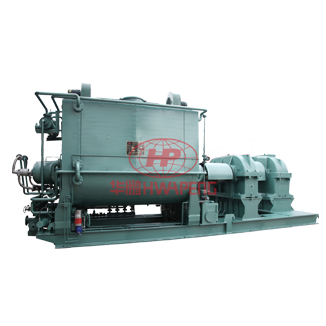

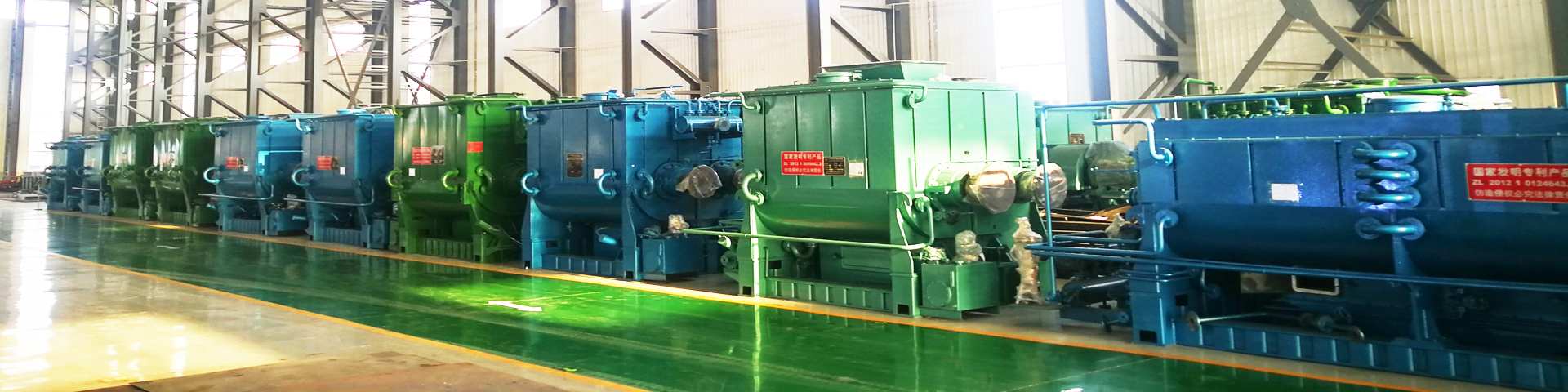

产品描述

HP-EVC800系列加压振动成型机主要用于生产预焙阳极,我公司将挤压机导向机构应用于阳极振动成型机,该振动成型机配备抽真空系统,结构简单,便于维护,配重及顶端模具定位精准,产品四角高度差小。

加压振动成型机组成部分:糊料输送装置、 均温凉料装置、计量供料装置、成型模具装置、振动成型装置、恒压加压装置、提升导向装置、辅助机架装置、入水冷却输送装置、抽真空系统、液压控制系统、电气控制系统。

生产能力:12-18 块/小时

阳极块规格:小于1900×1010×≤700(mm)

振动力:0-600KN 0-800KN

压重重量:13T

均温箱容积:8m³

计量仓容积:1.5 m³

在线咨询

在线咨询 在线留言

在线留言 产品文件

产品文件